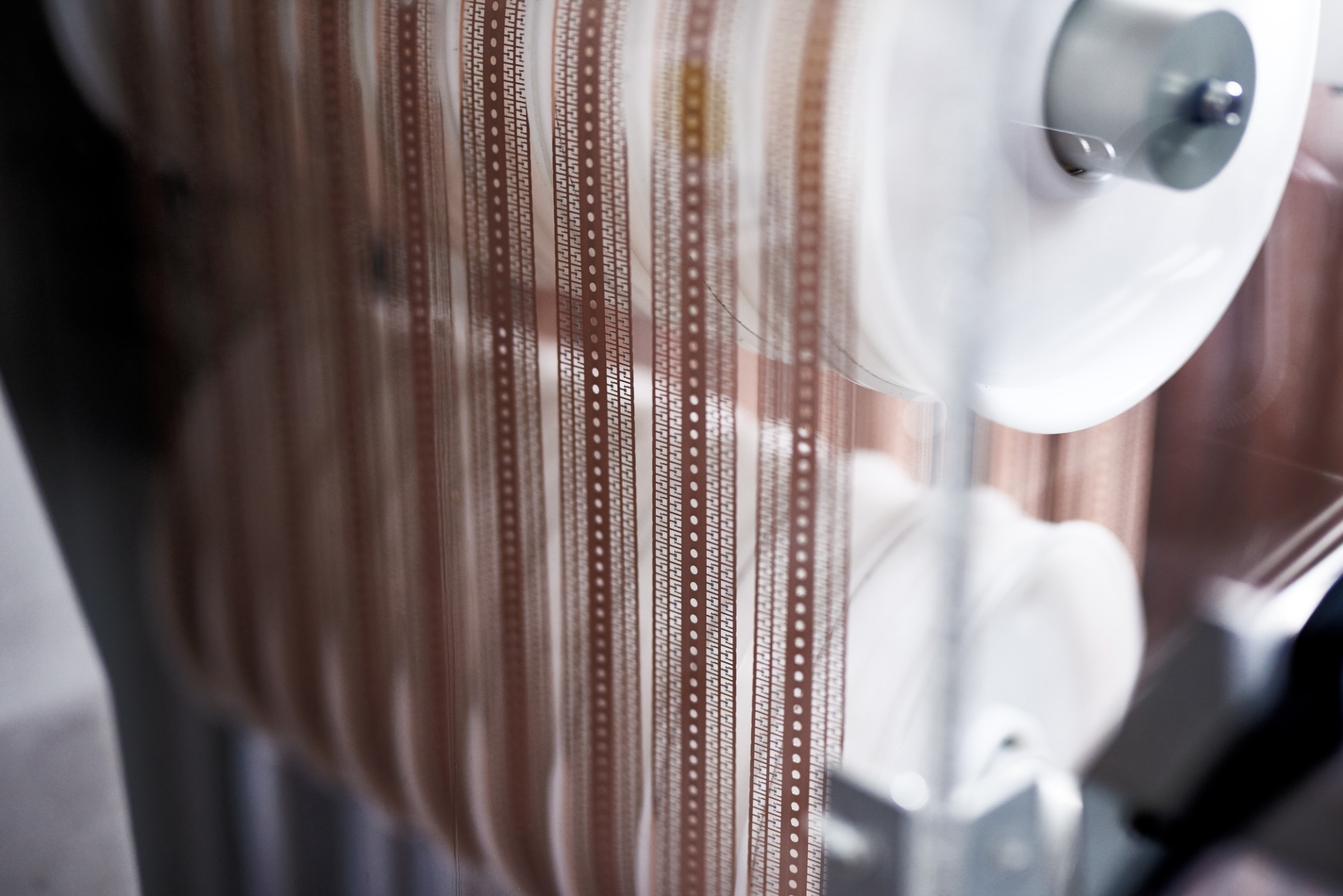

The only equipment on the market providing full ePassport, bankcard, and e-ID chipset module inspection

Work more efficiently, productively, and accurately with ultra-high-speed 2D vision inspection. This module is built with automatic high-speed reject removal to prevent sequence disruption. The PHIXEL CMR will guarantee your products' quality and eliminate product defects and field recalls — bringing customer complaints close to 0%.

Application

Inspection of Contact/Contactless Dual Interface (CDIF) module substrate to detect encapsulated die, mold defect, bonding wire, and plating defect

Key features

- Minimum 5MP colour camera for top and bottom inspection

- 4 stations for 2D inspection, testing, reject punch, and validation

- Throughput: up to 70,000 UPH (subject to package size)

- Post-inspection after reject punch

- Zero balancing capability, total good, and reject counts

- Customized AOI solution

- ID reader

- AOI cellular network architecture for recipe and EMAP management

- Lead frame width: up to 35 mm

- SEMI standard with SECS/GEM interface

- Option: real-time data feeding to MES and eSPC

- Option: auto email alert (defect/batch summary

Imaging system

- Camera: 5M pixels area camera mono

- Number of camera(s): 2 (top) + 1 (bottom)

- Resolution/Field of view: 15 µm/pixel, FOV:30 mm

- Minimum object detection: 3 pixels size

- Lighting: Compound lighting

Inspection categories

- Program mode: Fast programming for common reject criteria

- Reject treatment: Electronic map

- Inspection view: Top and bottom view

Inspection items

- CDIF defects: Incomplete punch. Incorrect punch. Contamination. Splicing connection (distinguish colour, size, and location). Mold void. Chipping. Die contamination. Loose wire

- Chip module defects: Bend lead. Chipping. Mold scratch. Gate remain. Mold contamination. Crack. Lead scratch. Mold flash. Incomplete fill. Scratch. Ink mark. Index hole deformation. Cold splicing. Shift punch

中文

中文