What sets our die attach solutions apart

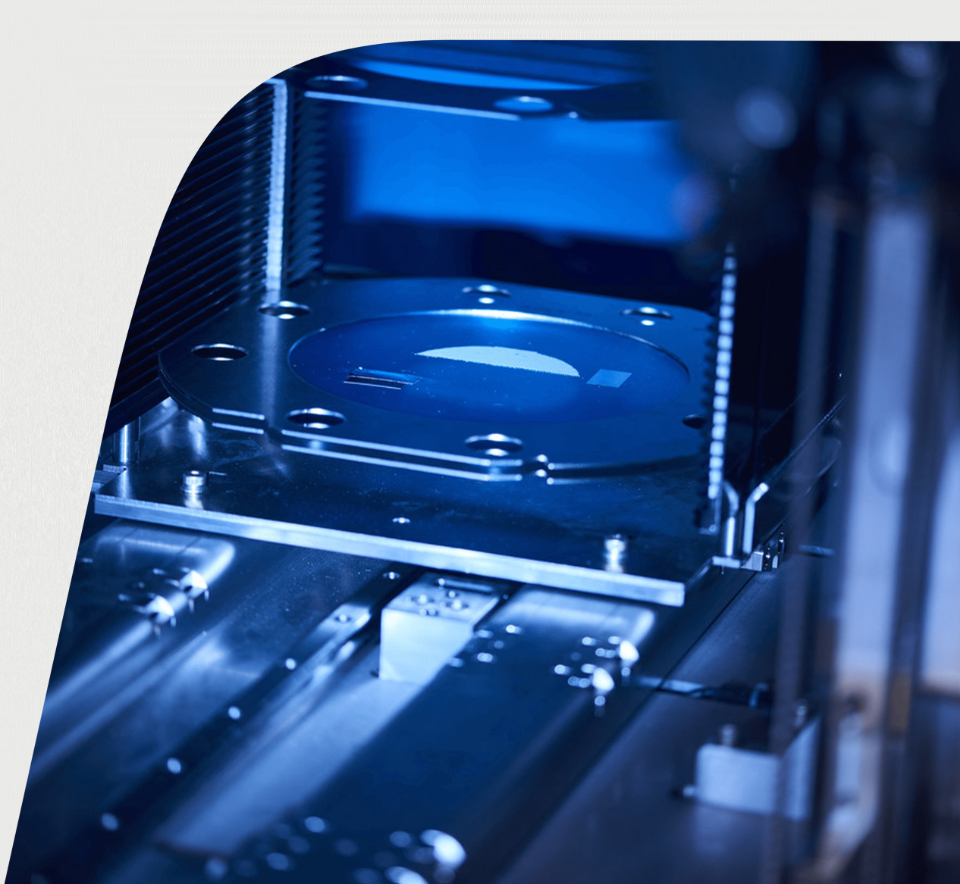

Multiple cameras at key process points help keep operation under close control. The machines perform high definition (up to 5 megapixel) inspections without sacrificing speed. XY accuracy is below 5 microns, which is increasingly important as die and feature sizes continue to shrink.

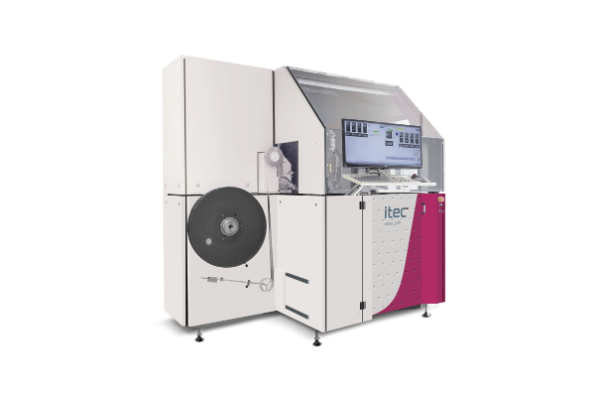

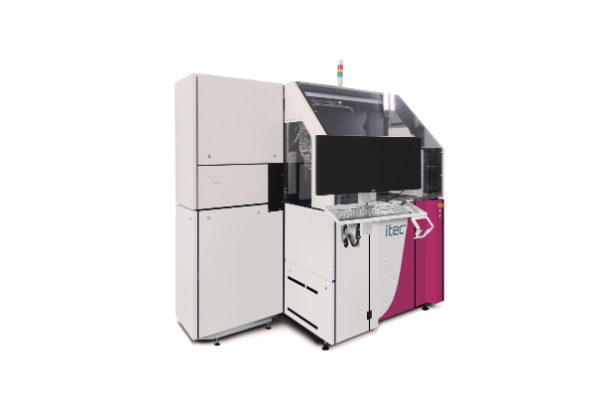

Systems are equipped with automatic wafer change for up to 300 mm wafers and comply with SECS/GEM and MES interface standards. Operating costs are further reduced by inbuilt versatility. We label all our ADAT3 machines XF (eXtra Flexible), because they can perform, in various applications – reel-to-reel, strip-to-strip and other types of die attach/bond – simply by reconfiguring them. So, you don't need to buy another machine when your or your customer’s requirements change.

Click on one of the product types below to learn more.

中文

中文