PHIXEL WIF

The PHIXEL WIF post-dicing AOI Wafer Inspection Frame system eliminates wafer damage due to dicing issues. It also inspects after package singulation of DFN (Dual Flat No-leads). The machine works at 60 slice wafers per hour and enables quick conversion for 6", 8", and 12" film carrier cassettes.

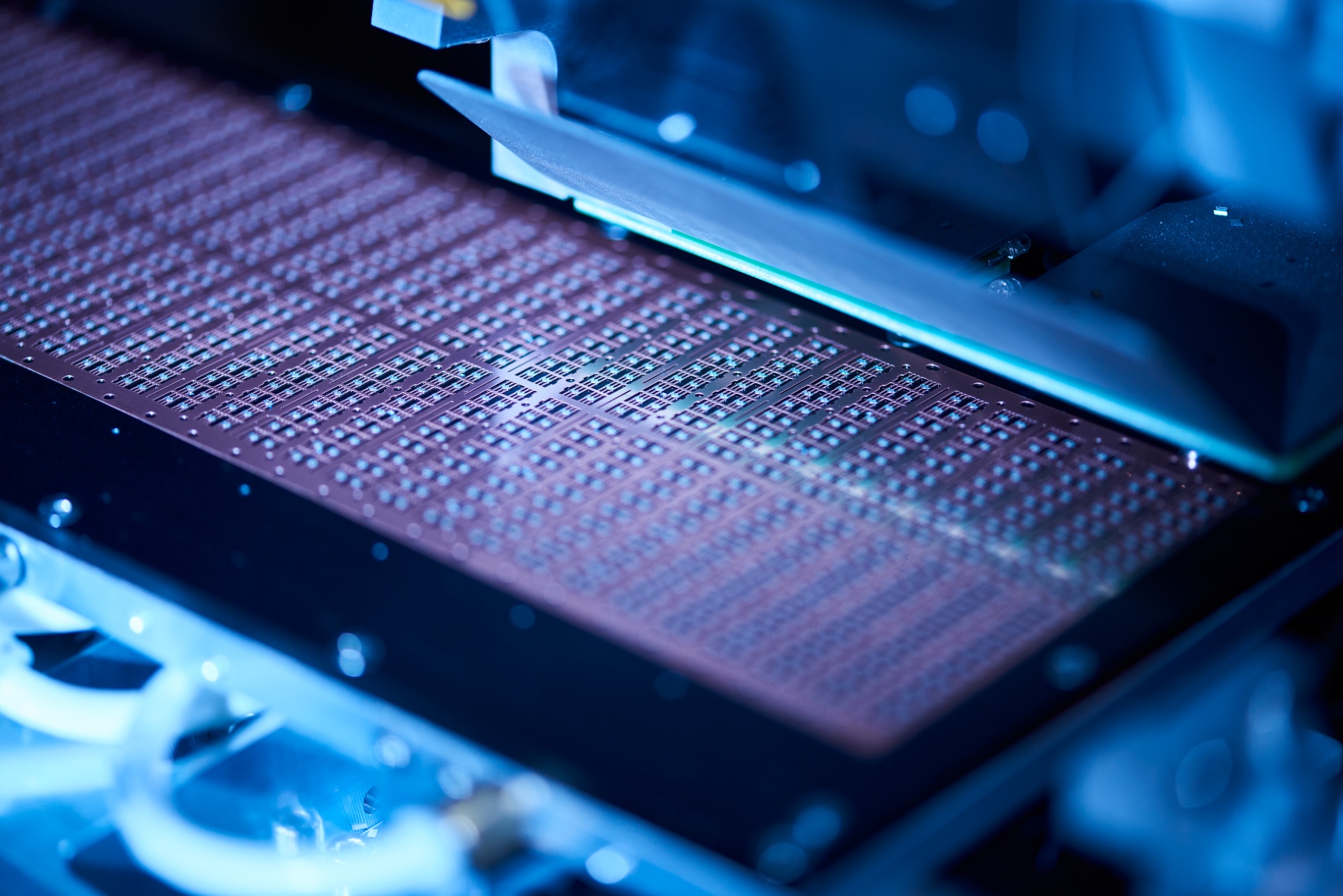

PHIXEL DWR

The PHIXEL DWR Die bond Wire bond Reel-to-reel system is the only 3D 3rd Optical inspection system for reel-to-reel products. It performs high-speed (up to 150,000 UPH) multi-row 3D lead-frame inspection. That guarantees the quality of die and wire bond, with automatic high-speed laser treatment for rejects.

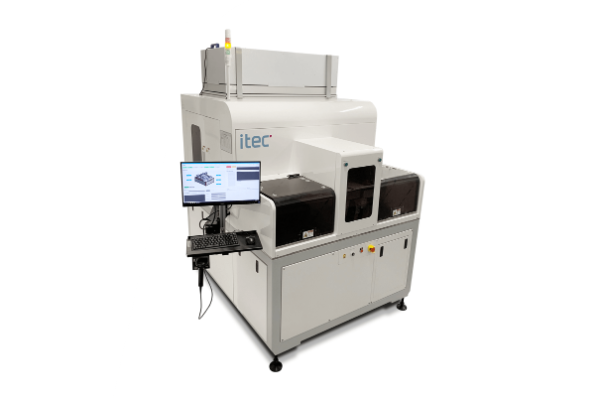

PHIXEL MIS

The PHIXEL MIS performs ultra-high-speed Mid-end Inspection Strip-to-strip inspection after plating to guarantee product quality. Throughput is up to 117,000 UPH depending on test/package size. It also works with the largest (100x300 mm) strip size.

PHIXEL CMR

The PHIXEL CMR for Contact and Contactless Modules Reel-to-reel is the only equipment on the market capable of performing full inspection of ePassport, bankcard, and e-ID chipset modules. It has ultra-high-speed (70,000 UPH) 2D top & bottom side vision inspection with high-speed automatic reject removal.

PHIXEL IHW

The PHIXEL IHW In-tape inspection Handler for Wide tape is the only post-tape inspection equipment providing full top & bottom side inspection. Working at up to 120,000 UPH, the carrier tape reel is convertible from 7 to 13-inch diameter, with auto conversion for different carrier tape widths up to 32 mm.

中文

中文