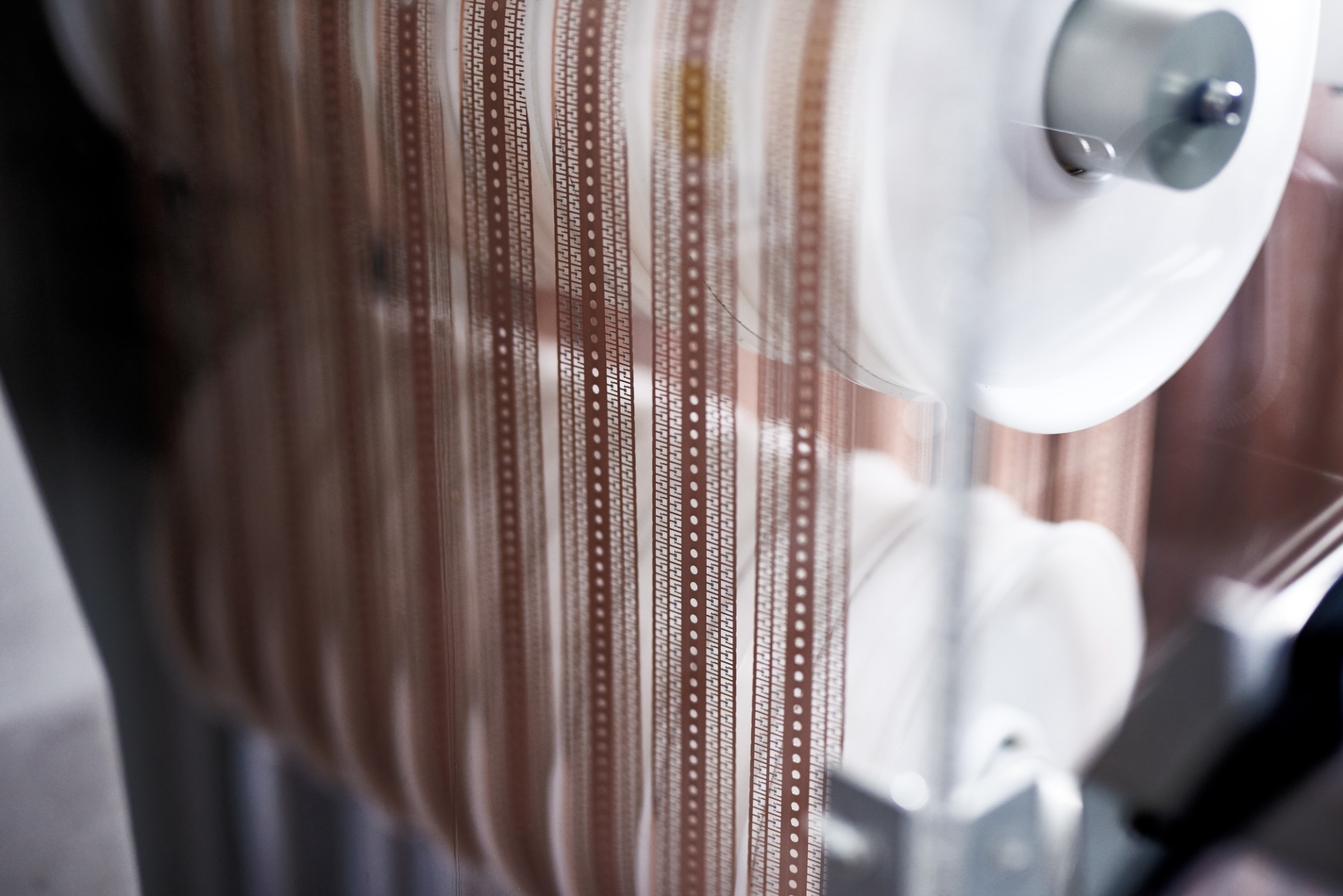

The only 3D inspection solution in the market for reel-to-reel products

Enhance your manufacturing efficiency and competitiveness with high-speed multi rows lead-frame 3D inspection, highly flexible customizable design with a simplex vision solution, and automatic high-speed laser treatment for rejects. When cost and quality of manufacturing are a concern, the 3D Post-Wirebond Reel-to-Reel Inspection guarantees the quality of die and wire bond — enabling fast feedback loop. The PHIXEL DWR minimizes waste and loss in manufacturing processes — eliminating defects usually only discovered during the electrical tests of finished products.

Inspection of lead-frame substrate to detect post-die bond and wire bond defect

Key features

- High-speed fully auto wire loop/profile inspection

- 3D inspection

- Laser cut option for reject handling

- Post-inspection after reject laser handling

- Throughput: up to 120k UPH (subject to package size)

- SEMI standard with SECS/GEM interface

- Sophisticated defect mode classification

- Lead frame width 17 mm to 36 mm

- AOI cellular network architecture for recipe and e-Map management

- Option: real-time data feeding to MES and eSPC

- Option: auto email alert (defect/batch summary)

Imaging system

- Camera: 5 M pixels area camera monochrome

- Number of camera(s): max 3 (1 or 2 inspection view + 1 post laser cut)

- Resolution/Field of view: 3 µm/pixel, FOV: 16 mm

- Minimum object detection: 15 µm

- Lighting: Compound lighting

Inspection categories

- Program mode: Fast programming for common reject criteria

- Reject treatment: Electronic map and laser (optional)

- Inspection view: Top and side view

Inspection items:

- Die defects: Foreign material

- Die placement: Glue on chip

- Wire defects: Ball shift. Sweep wire. Loop height. Sagging wire. Stray wire. Broken wire. Missing wire. Stitch off. Stitch offset

- Lead frame defects: Lead deformation. Lead shift. Lead lift up. Missing chip

中文

中文