For a fully automated, hands-off operation to increase your uptime and output

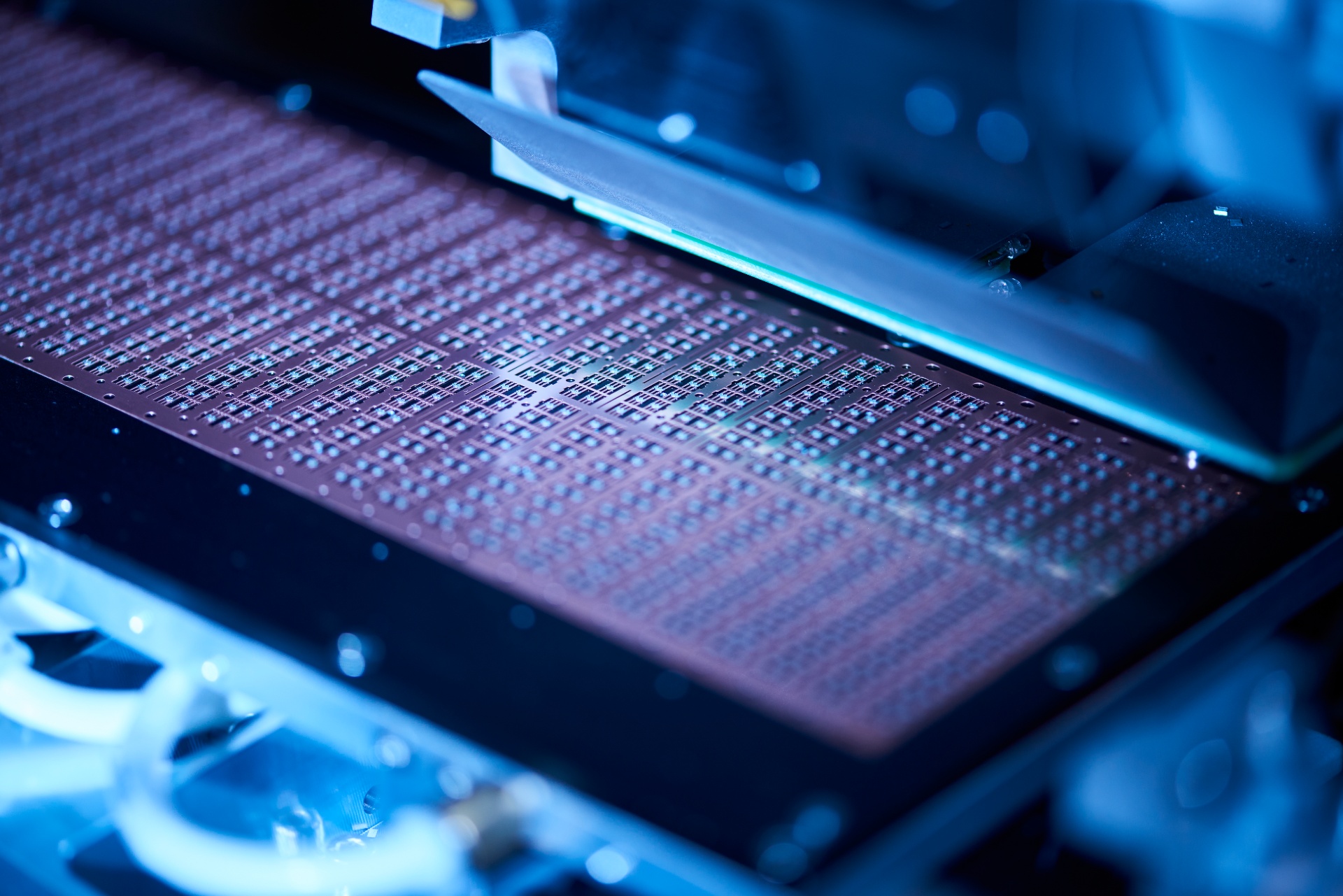

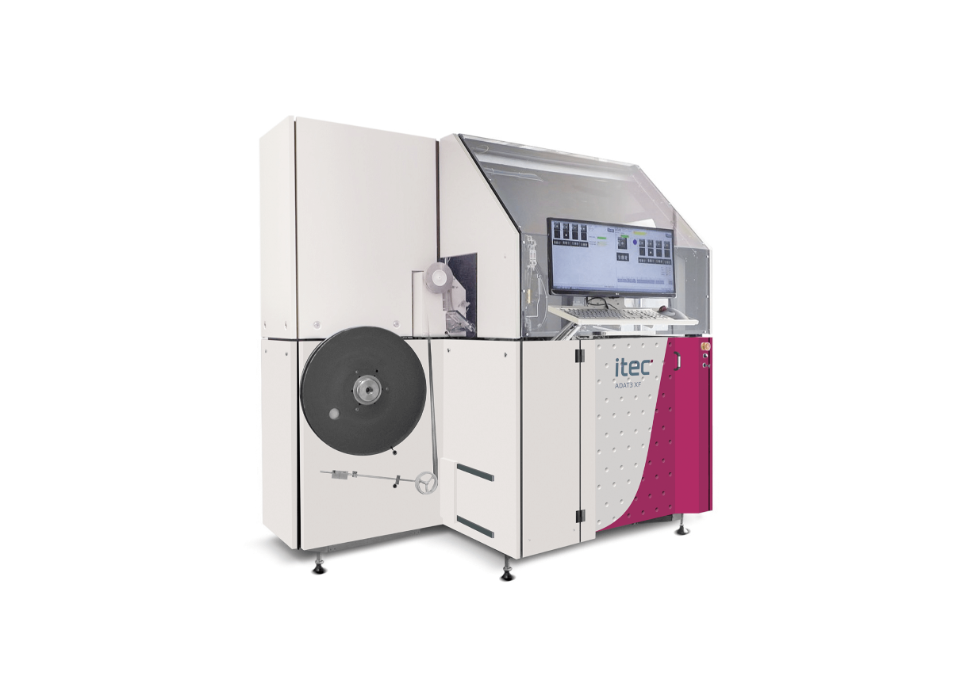

The Reel-to-Reel Eutectic Die Bonder supports all wafer map formats and is designed with high-definition optics for small-to-medium discrete products at extreme speed. With die alignment, backside chipping, die size measurement, and optional sidewall inspection for flat collets, the ADAT3 XF DBRE guarantees to enhance your production, product quality, and total cost of ownership.

Post-attach inspection:

Die present

Lead frame alignment XY

Black die detection

Surface inspection as a roadmap element.

Wafer handling:

Auto wafer change

Wafer expansion

Auto barcode reader

Extensive wafer mapping and wafer alignment functionality

Automation

Wafer map formats: Market standards. Full wafer map

Wafer map alignment: Start and reference die functionality.

Auto equipment setup: via Semiconductor Equipment Communication Standard (SECS) / Generic Equipment Model (GEM)

Traceability: ID input by barcode scanning

Connectivity

Connectivity via Semiconductor Equipment Communication Standard (SECS) / Generic Equipment Model (GEM) for automated set-up and die traceability

Automatic FFC wafer change for hands-off operation (AEC-Q101 compliant)

Flexible platform for all applications

Fits in XF (Extended Flexibility) platform architecture reel-to-reel lines

Convertible to other XF (Extended Flexibility) applications for leaded and leadless to cater for product mix flexibility

Optional lead frame, anti-tarnish, outgassing module.

Speed

48.000 dies per hour with roadmap to 60.000 dies per hour for small dies (≤ 0.4 x 0.4 mm)

Product size

200 x 200 um to 5 x 5 mm

Lead frame size

up to 32 mm wide

System accuracy

Small die (≤ 0.4 x 0.4 mm)

XY: 1 σ_xy ≤ 10 μm

Rotation: 1 σ_φ ≤ 1˚

Wafer handling

Wafer diameter: 8 inches, 6 inches on 8 inches Film Frame Carrier (FFC)

Wafer frame: Steel Film Frame Carrier (FFC) 8 inches or 12 inches

Foil tension: 8 inches, 1 - 10 mm

Wafer cassette: up to 25 slots

Die handling

Process Temperature: maximum 470 °C

Pickup force: 0.4 - 1.5 N ±0.1 N, Ultra-low (programmable) pickup force (20 grams)

Bond force: 0.2 - 1.5 N ±0.1 N

Mixed gas: customer-specific

Collet: pyramidal, flat

Ejector tool: single needle

Machine dimensions

Machine length, width, height: 2050 x 1250 x 2200 mm3

Net weight: 1850 kg

中文

中文