Enables early detection of production problems to prevent loss

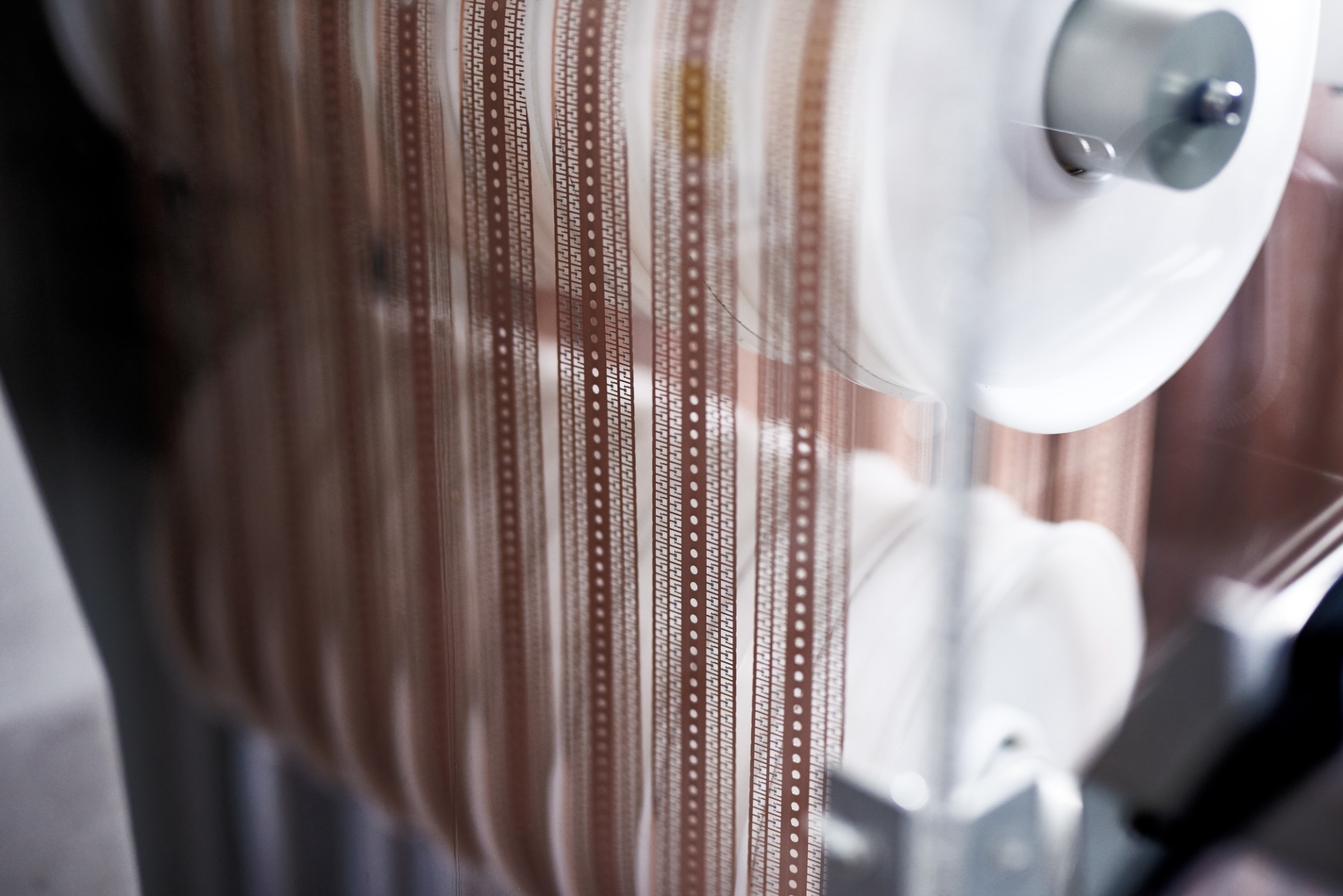

The Strip-to-Strip Inspection after moldng guarantees the quality of WIP products with fast feedback loop. When manufacturing cost and quality are a concern, the PHIXEL MIS minimizes waste and loss — enabling early detection of defects usually only discovered during the final 4th Optical inspection of finished products. With ultra-high-speed and high-precision 2D vision scans, as well as high-precision laser for reject treatment, PHIXEL MIS helps to achieve best-in-class throughput.

Inspection of lead-frame substrate to detect package dimension, molding and plating defect

Key features

- Dual stations for 2D inspection and laser marker

- Throughput: Up to 117,000 UPH (subject to package size & leadframe density)

- Support max 100 mm x 300 mm substrate LF size

- 3-4 magazines for on/off loaders

- Auto-lead frame QR code reading

- Full strip laser mark option

- Vacuum system and brush clean for package laser mark

- AOI cellular network architecture for recipe and e-Map management

- Option: real-time data feeding to MES and eSPC

- Option: auto email alert (defect / batch summary)

- SEMI standard with SECS/GEM interface

- Advanced Defect Classification (ADC)

- Reject treatment: Electronic map and auto punching (optional)

Imaging system

- Camera: 8K or 16K color line-scan camera

- Number of camera(s): 2

- Resolution/Field of view: 3.17 to 6.3 µm / pixel, FOV 50 mm to 100 mm

- Minimum object detection: 12 to 25 µm

- Lighting: Compound lighting

Inspection categories

- Program mode: Fast programming for common reject criteria

- Reject treatment: Electronic map and auto punching (optional)

- Inspection view: Top and bottom view

Inspection items:

- Moulded lead-frame defects: Chipping. Body broken. Scratch. Pin hole or void. Mold shift. Incomplete mold. Gate remain. Foreign material. Gate chipping. Rough surface. Melted Body. Blister. Body crack. Bubbles

- Lead-frame defects: Flash along lead. Cu exposure. Contamination. Bend lead or twisted lead. Mould compound leakage on lead. Burr. Missing lead. U-shape flash (mold flash under lead-frame). Indexing hole deformation. Mold flash. Lead press. Lead width. Empty (no encapsulation)

中文

中文