For the highest productivity and quality standard at the lowest cost of ownership

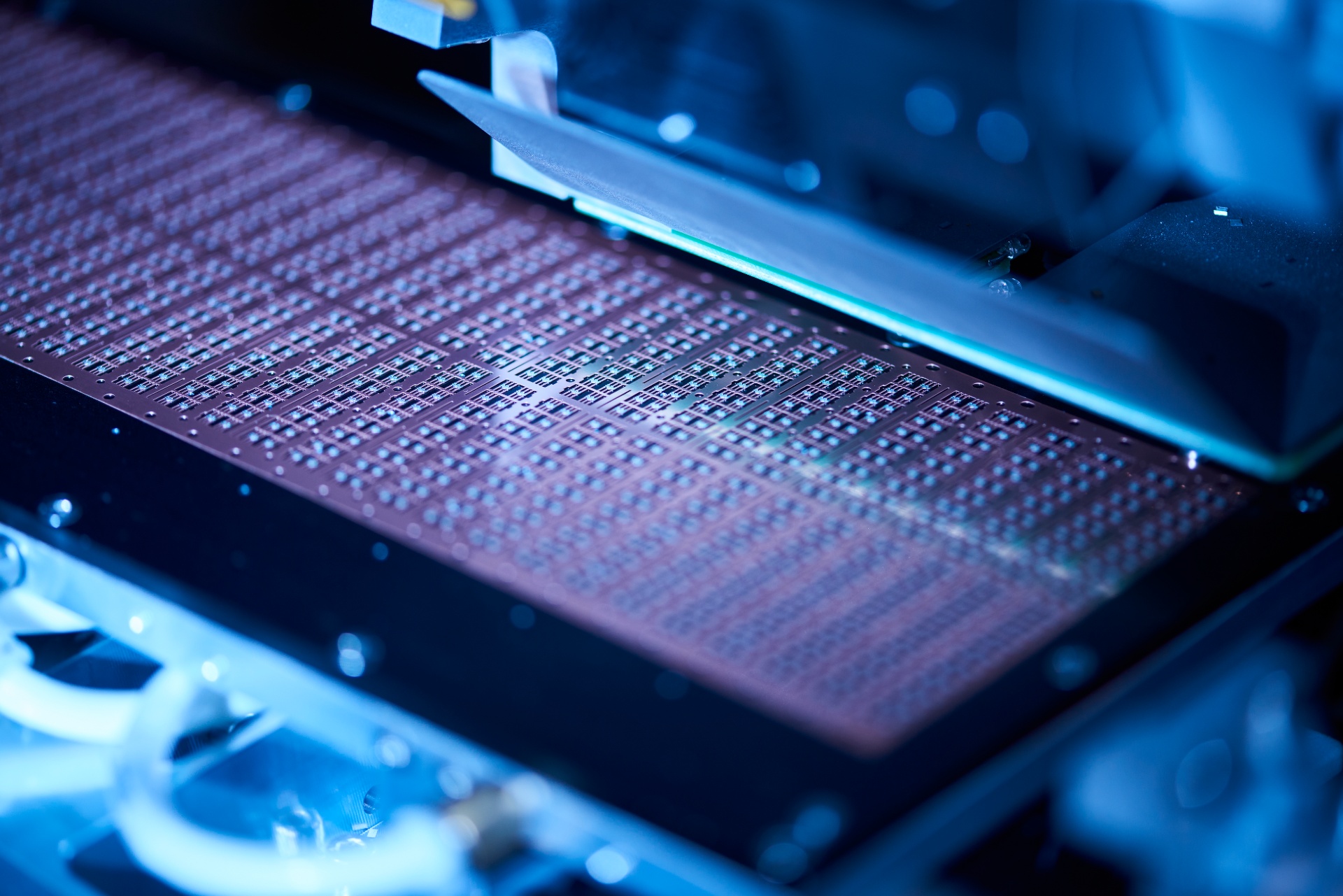

Curing in milliseconds versus seconds in the current industry practice, the ADAT3 XF Tagliner is three times faster and 30% more accurate than anything on the market. Common systems only work with transparent web material; this Tagliner handles a diverse range, including paper enabling you to move away from PET plastics for sustainability. Eliminating manual handling through automated wafer change and qualified for die bond of all known ICs down to 200 μm die size, the ADAT3 XF Tagliner performs a complete inspection without sacrificing speed and productivity.

Performance

- 48.000 units per hour with the machine speed up to 50.8 mm web pitch

- High-precision die-attach

- Works with both transparent and non-transparent web material

- High-precision glue dispense system

- High-speed thermal compression curing system. Easy maintenance, one or two thermodes only

- 100% high-resolution optical inspections on glue, die, attach and cure processes — without compromising machine speed

- Process fully qualified for major chip suppliers at the industry's tightest reliability requirements: temperature, humidity, and mechanical.

- 8 to 12 inches wafer compatible with fully automatic wafer change

- Capable of handling dies down to 200 µm

- Single-track design for easy operation and change over

- Integrated with BW Paper systems, winding/conversion systems and quality control solution by Voyantic.

Speed

- 48.000 units per hour flip chip up to a web pitch of 50.8 mm

Die Range

- Die size: 200 x 200 µm to 5 x 5 mm

- Web width: 40 - 165 mm, single row operation

Placement accuracy

- Die position: x, y: < 9 µm (1σ)

- Die rotation φ: < 0.67 deg (1σ)

- Pick and place force: 0.2 - 1.5 ± 0.1 N

Dispense accuracy

- Dot size accuracy: < 10 µm (1σ)

- Dot position accuracy: < 10 µm (1σ)

- Dot diameter: >200 µm

Cure system

- 2 stitch units, thermo compression cure

- Cure temperature range: 20 … 500 ± 5 °C

- Cure force range: 0 - 20 ± 0.5 N

- Cure time range: 0 - 5000 ms

QA vision inspections

- Glue dot size and -location

- Die top-side before attach

- Die bottom-side before attach

- Glue presence before attach

- Die presence before cure

- Die placement and rotation

Wafer handling

- 8 and 12 inches

- Steel/plastic Film Frame Carrier (FFC)

- Automatic wafer change

- Wafer expansion

- Automatic barcode reader

Subsystems

- BW Paper Systems

- Winder/Unwinder

- Voyantic Reader

Machine dimensions

- Length, width, height: 5397 x 1500 x 2617 mm

- Net weight: 5230 kg

中文

中文