Ready for next-generation LED direct view displays

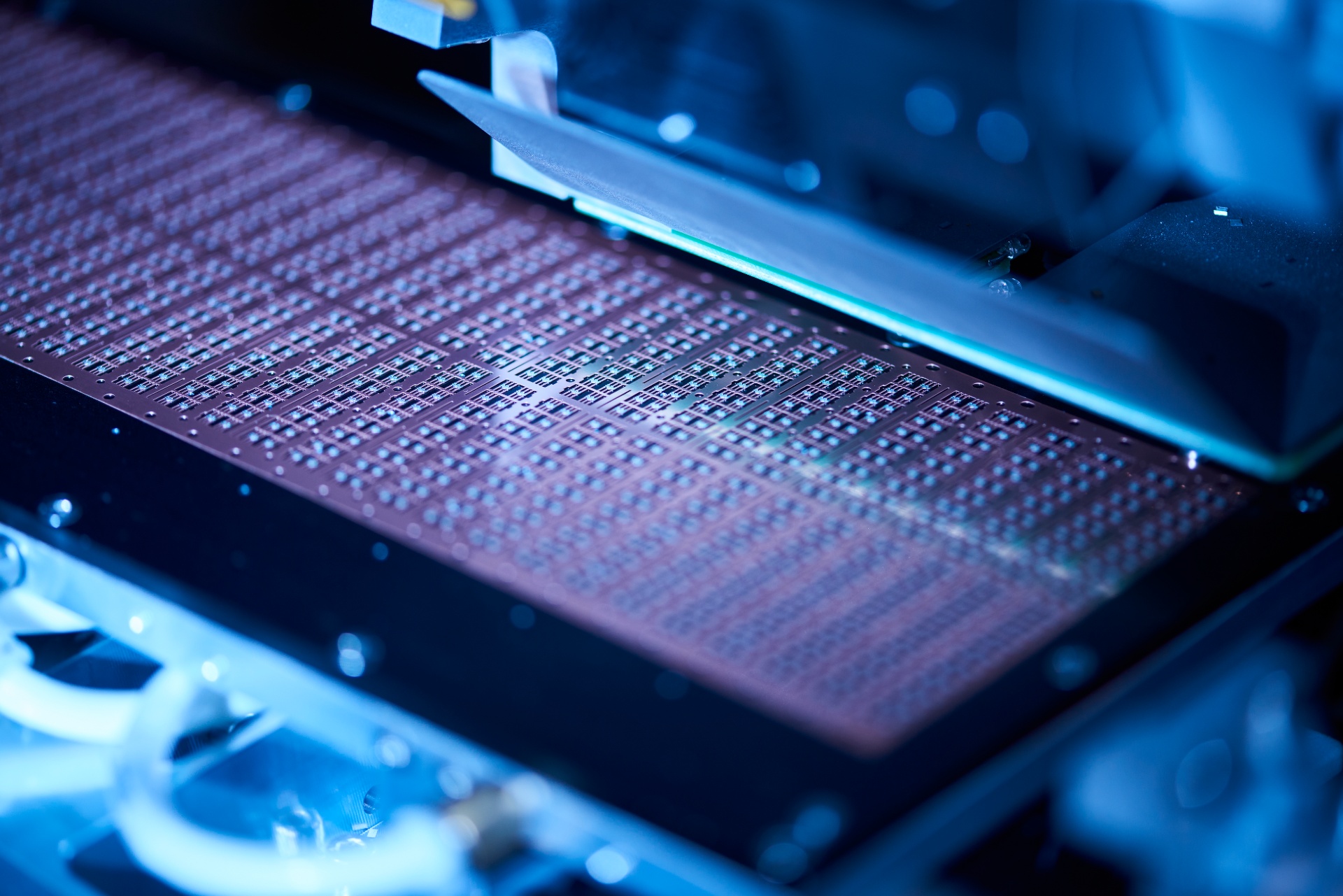

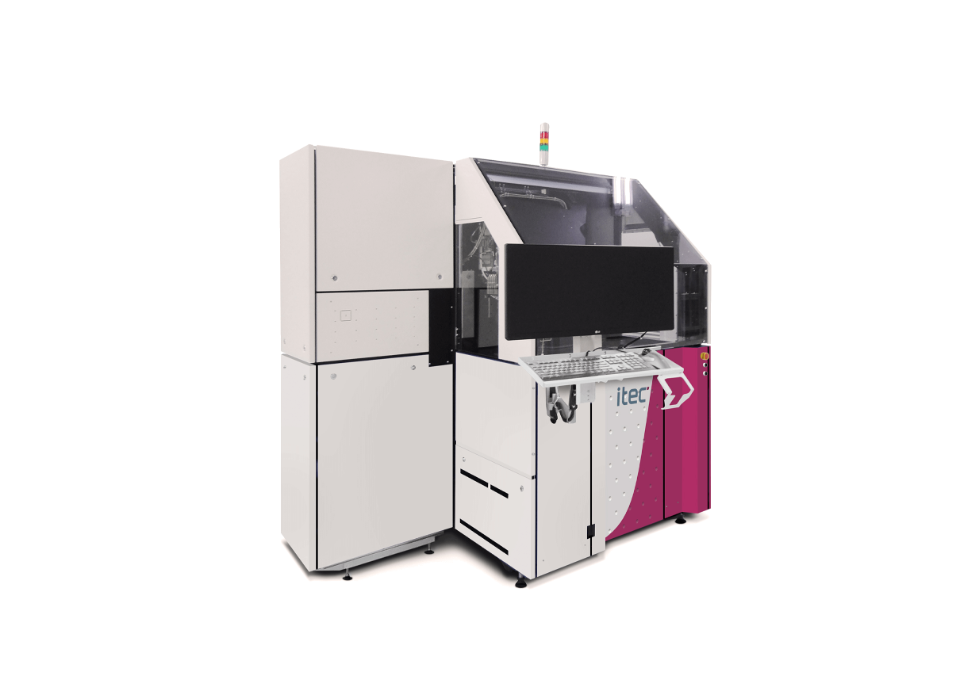

Reduce your total cost of ownership. Gain quality inspections and the flexibility to scale — without compromising on accuracy, quality, or speed. The ADAT3 XF PiXelect Bonder is four times faster than anything on the market — handling LED as small as 3x5 mil. The flip-chip bin-mixing technology eliminates the sorting step and manual wafer change. Multiple systems can be connected — enabling you to build competitive, high-definition, and cost-effective displays using mini-LED technology.

Performance

Bonding 70.000 units per hour

Handles the smallest LED sizes on the market

Flip and non-flip configuration at same speed

Standard deviation XY position better than 3 μm

Handles sorted as well as EPI wafer input (sorting and bonding integrated in one step)

100% high-resolution optical inspections on die, attach, and post-bond steps without compromising on machine speed

8 inches Film Frame Carrier (FFC) ring with fully automatic wafer change

Can be configured for manual load as well as conveyor belt interface with a series of systems (Red/Green/Blue (RGB) line)

Can handle R, G, B colours in single machine with placement gap down to 20 μm

Speed

70.000 units per hour flip-chip bonding

Die Range

Length, width: 75 x 125 μm to 2.5 x 2.5 mm

Aspect Ratio: 1:1 - 1:3

Thickness: 50 - 400 μm

Substrate range

Minimum: 75 x 75 x 0.1 mm

Maximum: 250 x 250 x 2 mm

Placement Accuracy

Die position: x, y: 1σ ≤ 3µm

Die rotation: φ: 1σ ≤ 1°

Pick and place force: 0.2…1.5 ± 0.1 N

Pick up tooling

Vespel collet

Rubber tip

Four sided collet

Push-up needle

Substrate Handling

Manual

Optional conveyor belt interface with a series of machines (RGB line)

QA Vision Inspections

Pre pick inspection (wafer): Die alignment. Frontside chipping. Wafer map alignment

Pre pick inspection (PKG carrier): PKG alignment

Frontside chipping. Carrier map alignment

Post pick (transfer): Die present. Die alignment

Pre-bond inspection on substrate: Bond pad alignment

Post bond inspection incl. substrate recognition: Die placement

Wafer handling

Handling R, G, B wafers: EPI or Sorted

8 inches Film Frame Carrier (FFC) ring

Automatic wafer change

Wafer expansion

Automatic barcode reader

Automation

Full die traceability (full strip mapping)

Auto recipe download (MES interface)

Monitoring of critical process parameters during production. Automatic stop function when parameter out of control

Servo, bond-force and vacuum auto-diagnostics functionality to check health status of the machine

Machine dimensions

Length, width, height: 2050 x 1280 x 2100 mm3

Net weight: 1850 kg

中文

中文