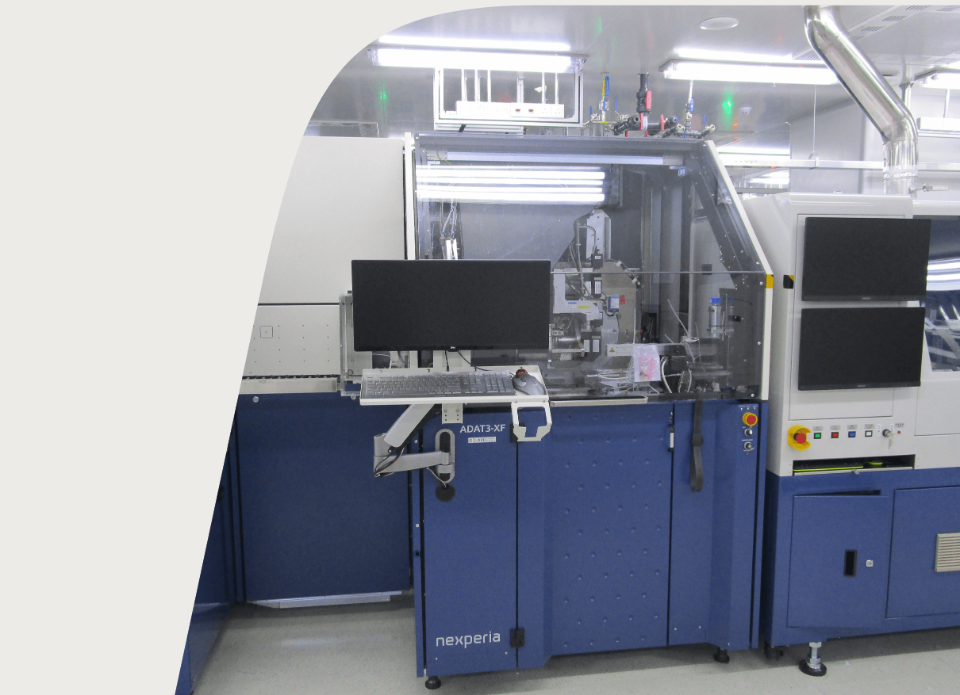

A breakthrough in cost, quality, and productivity

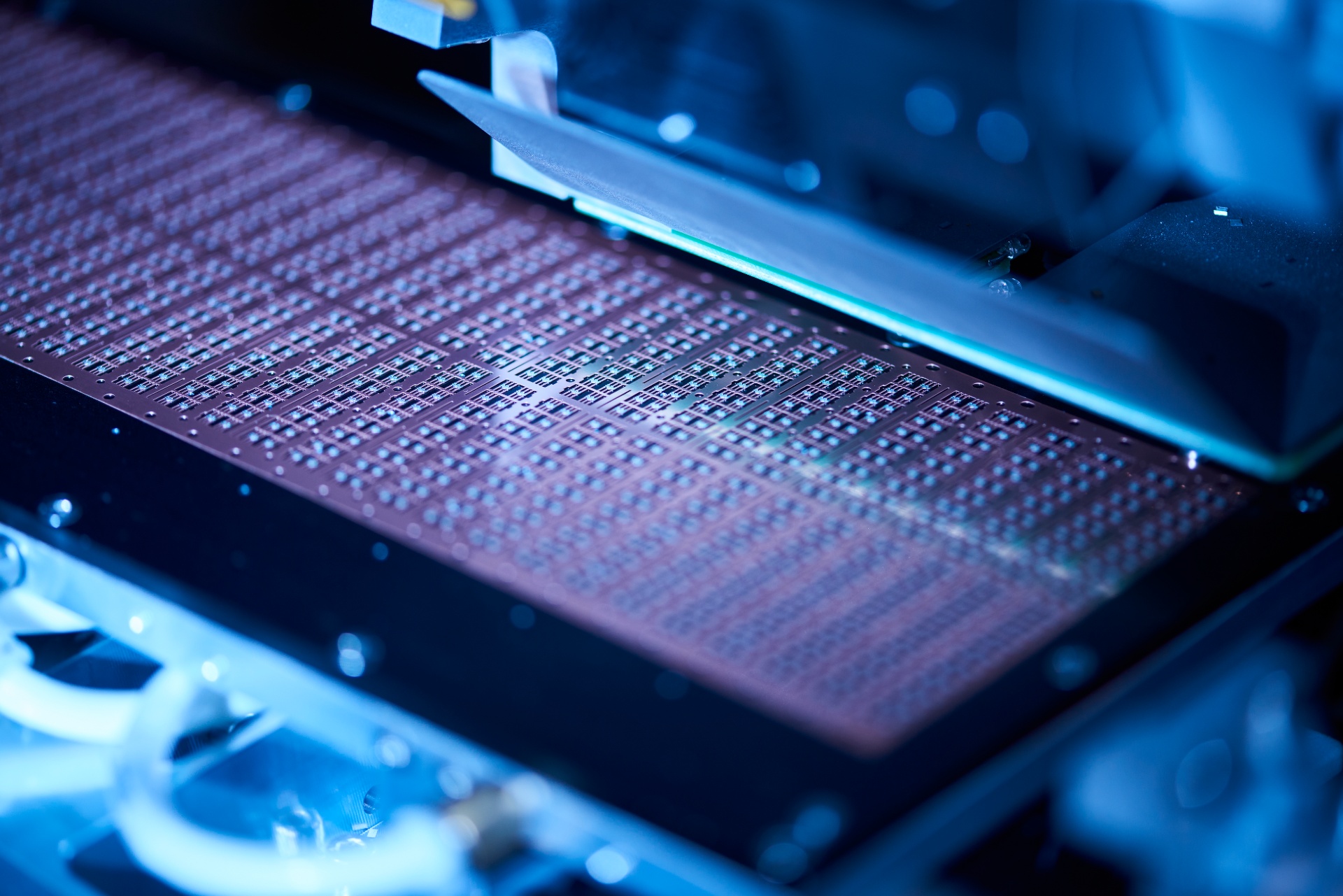

The only product in the market offering an in-line strip-to-strip die bonder solution. The ADAT3 XF DBS receives strips directly from one machine, processes them, and feeds them to the next — maximizing your productivity. Handling ultra-small and medium die at unparalleled speed, it easily connects to top and bottom screen-print equipment. This die bonder is also equipped with automated wafer change and high-definition optics for on-the-fly quality inspection.

Performance

Up to 60.000 units per hour

Supports 8 to 12 inches wafer on frame film carrier

Strip size

100 x 300 mm

Solder paste/Glue

Die size

Minimal: 0.2 x 0.2 mm

Maximum: 7 x 9 mm

High throughput at high-volume manufacturing rate

Belt in, belt out

Full die traceability (strip E142 – wafer)

Auto recipe download: Manufacturing Execution System (MES) interface

SECS/GEM interface with E142

Solder paste power application, SO8, DPAK, and SOD123/128 SOT669

Speed

Up to 60.000 units per hour (depending on die size, lead frame pitch, glue/solder type and selected quality inspections)

Die Range

Length, width: 0.2 x 0.2 mm to 7 x 9 mm

Aspect Ratio: 1:1 - 1:3

Thickness: 50 - 400 µm

Lead frame size

Minimum length, width: 100 x 40 mm

Maximum length, width: 300 x 100 mm

Thickness: 0.1 - 1.0 mm

System accuracy

Small die (≤ 1 mm): XY: 1 σ xy ≤ 5 μm. Rotation: 1 σ φ ≤ 1˚

Large die (≥ 1 mm): XY: 1 σ xy ≤ 5 μm. Rotation: 1 σ φ ≤ 0.3˚

Pick and place force: 0.2-1.5 ± 0.1 N

Wafer handling

Wafer size: 6 - 12 inches

Wafer frame: 8 - 12 inches

Steel/Plastic Film Frame Carrier (FFC)

Foil Tension: Programmable expander (8 inches: 1 - 10 mm, 12 inches: 1 - 15 mm)

Automatic wafer change and expander

Automatic barcode reader

Lead frame handling:

Conveyor belt loading and unloading according SMEMA protocol

Pick up tooling

Vespel collet

Rubber tip

Four-sided collet

Push-up needle

Imaging system

Number of cameras: 4

Resolution/Filed of View (FOV) glue: 0.3 MP camera (3.2 UM/pixel), FOV 2.1 x 1.4 mm

Resolution/ Filed of View (FOV) pick-up and backside: 5.0 MP camera (2.3 UM/pixel), FOV 5.6 x 4.7 mm

Resolution/ Filed of View (FOV) post-bond: 5.0MP camera (4.6 UM/pixel), FOV 11.3 x 9.4 mm

Resolution/ Filed of View (FOV) sidewall: optional

Minimal object detection: 10 micrometres (μm)

Lighting: coaxial and ring light, including multicolor light

Inspection categories

Program mode: Fast programming for common reject criteria

Reject treatment: Strip map (E142) and reject bin

Inspection view: 4 cameras, (1) glue, (2) pre pick

(3) back, (4) post-bond

Inspection items

Die-related: Top chipping, backside chipping. Damaged. Die size/die ratio. Scratch. Cracked die. Discoloration

Glue-related: Drop size. Drop shape

Post-bond related: Die alignment (position, size, rotation). Glue fillet

Automation:

Wafer map SEMI E142 format, SECS-GEM mpa exchange

Start and reference die functionality

Automatic Product Replacement

MES Interface including auto recipe download

Monitoring of critical process parameters during production. Automatic stop function when parameter out of control

Servo, bond-force and vacuum auto-diagnostics functionality to check health status of the machine

Machine dimensions

Length, width, height: 2200 x 2100 x 1250 mm3

Net weight: 1950 kg

中文

中文