Turning disruptive technology into market-leading solutions

At ITEC we don’t just build equipment. We engineer solutions to our customers’ challenges. And that means constantly adapting to the trends of the industry and enhancing our in-house technologies. We’ve developed dedicated die bonders and sorters for RFID inlays and mini-LED displays. Our production testers for discrete products are among the fastest and most accurate on the market. And we use machine learning in our advanced AOI systems to find production defects in discretes and ICs. We specialize in disruptive technology – delivering solutions that bring you unique benefits.

We partner with each customer to learn about the challenges they face. Do you want to cut back your production costs without sacrificing quality? Or do you find yourself being more and more concerned about your existing production equipment and its lack of speed, accuracy, or flexibility? Together we will find the right solution for your specific need. We see ourselves as a solution provider, and we’re masters at reducing your total cost of ownership.

Take a closer look at our solutions.

Download our product catalogue

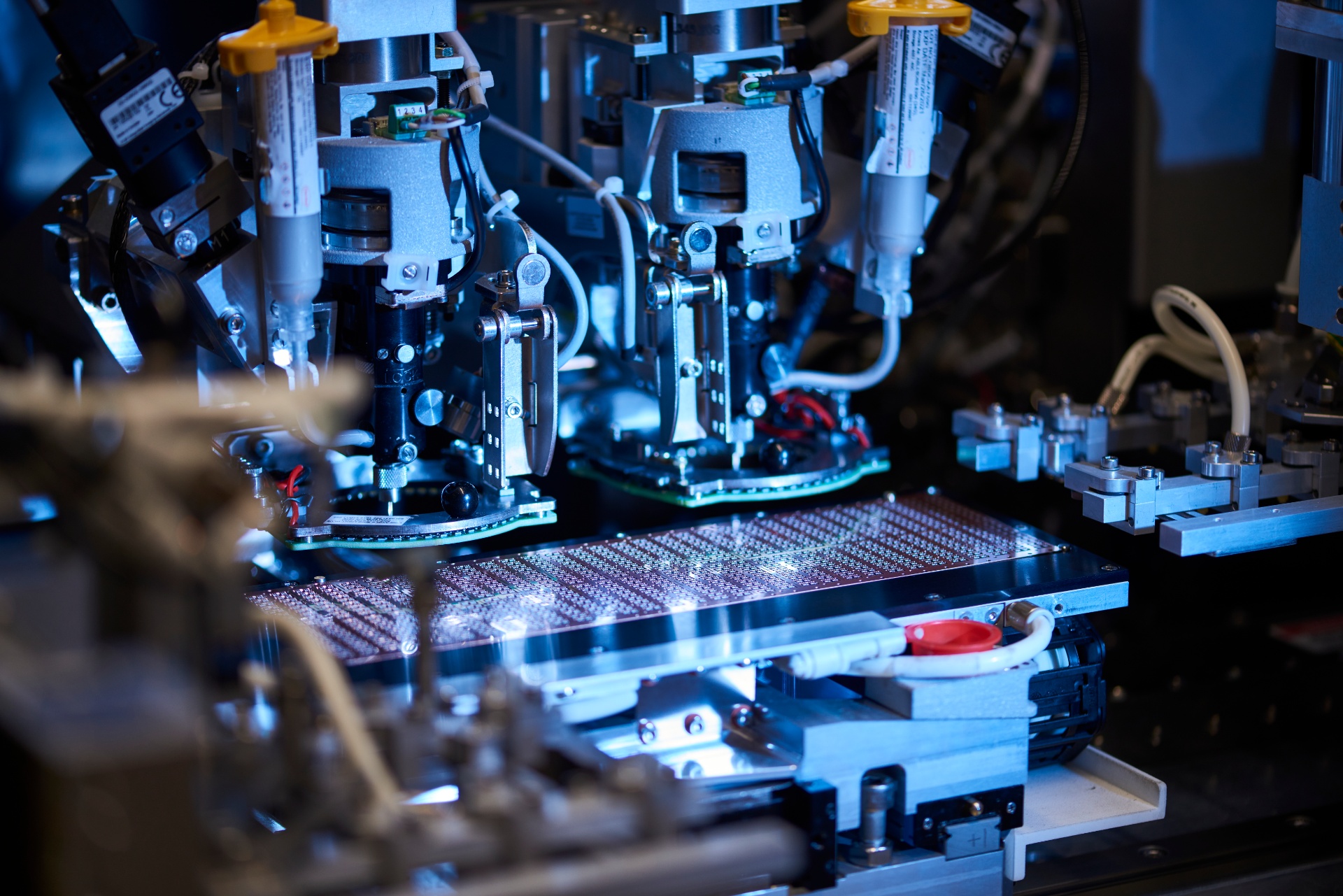

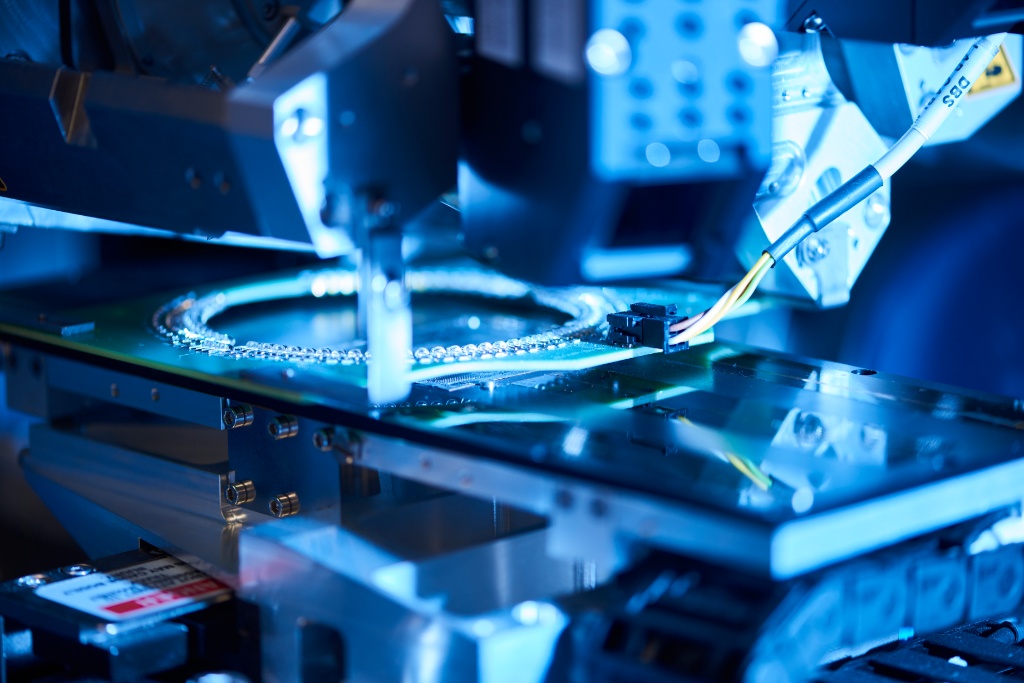

Die attach - high volumes bring low costs

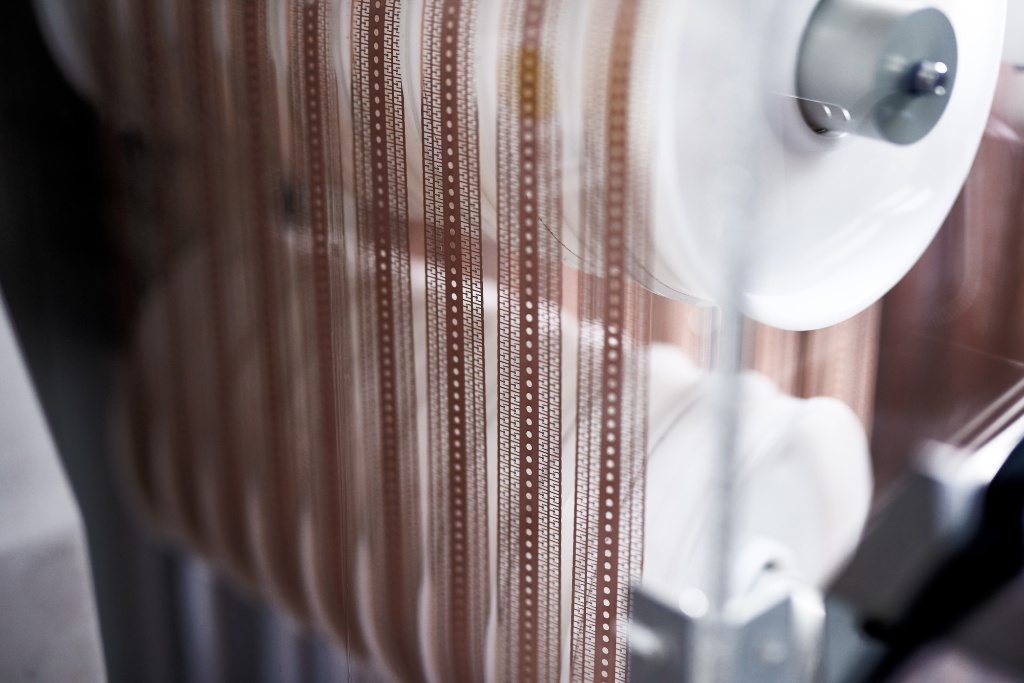

Our ADAT3 XF range includes the fastest and most advanced Die Bonders and Die Sorters on the market. Most operate at up to 60,000 uph so you need fewer machines to do the work, which reduces running costs. ADAT3 XF is one of the most versatile solutions around and can be tailored to your needs for Strip-to-Strip (Glue/DAF/Eutectic), Reel-to-Reel (Eutectic), and Flip Chip applications. For RFID Inlays, the ADAT3 XF Tagliner is built on proven technology and capable of 48,000 uph. For mini/micro LED displays, where accuracy is essential for stitching together LED displays, the ADAT3 XF miniLED die bonder still manages to achieve speeds of up to 70,000 uph. If you want to combine high productivity, high quality and the lowest cost of ownership with record-breaking output take a look at the ADAT3 XF range.

Learn more

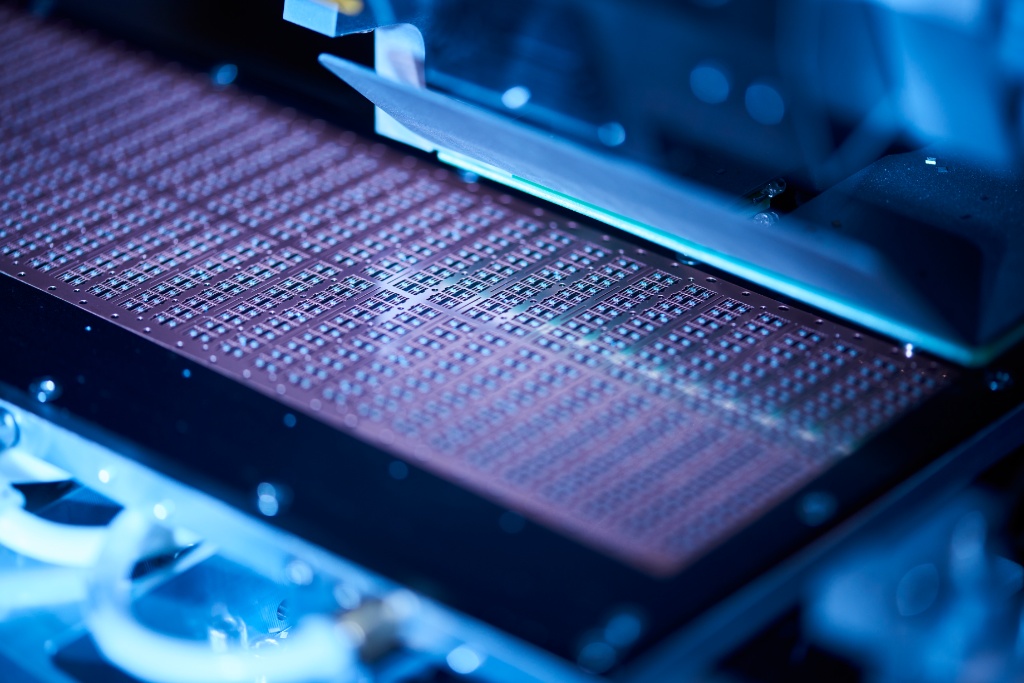

High volume testers for discretes

Our Parset family is the industry benchmark for high-speed semiconductor production testers and has set the standard for discrete testing for the last 30 years. There are three models (µParset, Power µParset, and nanoParset), and they offer the fastest test-times in the market, with speeds of up to 90,000 uph (for the nanoParset combined with dual-track handler). These high-speed production testers are flexible and extendable and work seamlessly with any handler and wafer prober.

Read more

High speed automated optical inspection

Our PHIXEL AOI family helps improve front-end and back-end semiconductor productivity significantly by identifying device defects that are usually only discovered during electrical test of finished products. Smart implementation at critical inspection points is the key. We offer inspection solutions for 2nd Optical, 3rd Optical, 4th Optical, mid-end inspection applications (after mold and plating) and full inspection for chip modules too — both inline and standalone. These ITEC solutions combine deep learning and traditional algorithms in machine vision to ensure the highest quality.

Learn more

Hassle-free service

Our portfolio of solutions goes beyond equipment. We offer hassle-free Service solutions tailored to meet your precise needs, whether that is a full-service package where we take care of everything, or training for your staff so you can service the equipment yourselves.

中文

中文