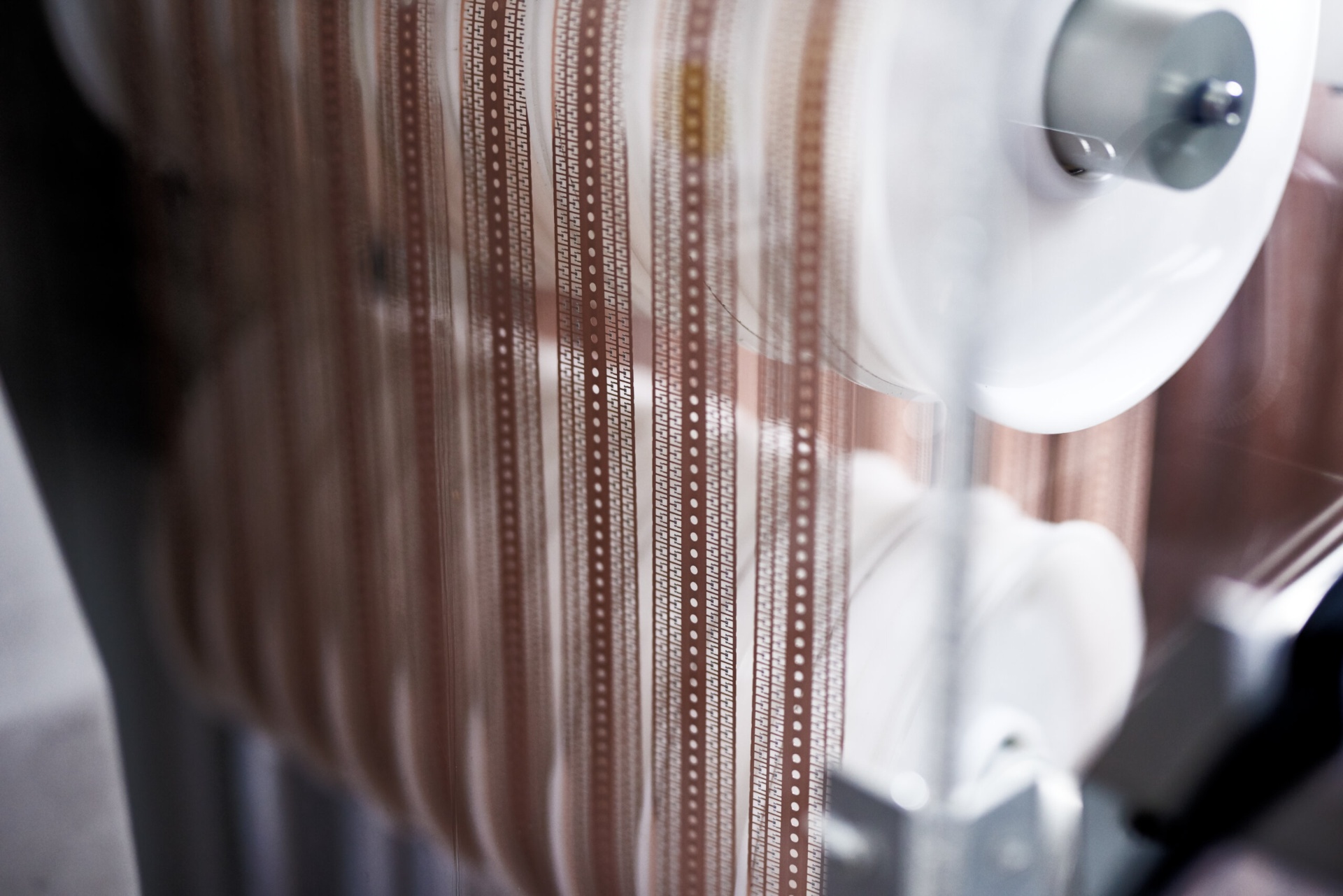

The only post-tape inspection equipment on the market providing full inspection capability

Guarantees the quality of the products you produce and deliver. The Post-Seal In-Tape Inspection eliminates quality defects — bringing customer complaints and field recall rates close to 0 PPM. The PHIXEL IHW has a fast convertible for 7-13-inch” carrier tape reel diameter and auto conversion for different carrier tape widths up to 32mm. With AOI cellular network architecture for recipe management and Advanced Defect Classification (ADC) by hybrid analysis, the Post-Seal In-Tape Inspection outperforms market competition to go above and beyond your customers’ requirements.

Inspection after taping to detect orientation, lead, mark, seal, package surface defect, reel label and quantity

Key features

- AOI cellular network architecture for recipe management

- Reel size: 7" to 13"

- Throughput: up to 120,000 UPH (subject to package size & pitch)

- Package: leaded, leadless, and WLCSP

- Carrier tape width: 8 to 32 mm (auto track width)

- Advanced Defect Classification (ADC)

- SEMI standard with SECS/GEM interface

- Option: tilted lead defect vision

- Option: real-time data feeding to MES and eSPC

- Option: auto email alert (defect/batch summary)

Imaging system

- Camera: 5M pixels area camera monochrome

- Number of camera(s): 2: 1 (top) + 1 (bottom)

- Resolution/Field of view: 4 - 16 µm/pixel FOV: 10 mm to 40 mm

- Minimum object detection: 16 µm

- Lighting: Compound lighting

Inspection categories

- Program mode: Fast programming for common reject criteria

- Reject treatment: Electronic map

- Inspection view: Top (and angle camera for lead lift up defect as upgrade option)

Inspection items

- Marking defects: Unclear mark (faded character). Shift mark (misaligned marking). Incomplete mark. Double mark (multiple character). Vertical mark (wrong orientation). No mark. Mixed marking

- Moulded Package defects: Bubbles/bulge. Voids/pin holes. Crack. Broken body. Chipping Scratch. Unmoulded. Incomplete fill. Foreign material

- Lead Package defects: Mould flash on/along lead. Foreign material and contamination. Exposed wire/clip. Ejector mark. Visible wire. Solder bridging. Bent lead/lead angle. Lead sweep. Lead spacing/span. Lead cuts/depressions/damage. Lead burr. Missing lead. Lead length. Incomplete lead forming.

- Taping defects: Loose/unseal cover tape. Cover tape misalignment. Damaged/contamination cover tape. Deformed/damaged cavity. Damaged bottom tape. Chipped/broken body. Mixed product. Edge sealing. Unseal tape. Offset sealing. Cover tape tearing. Product tilting

中文

中文