Revolutionary flip-chip die bonder assembles 60,000 chips/hour

Flip chips have two key benefits over the wire-bonded chips they replace. They eliminate the quality problems associated with wire bonds, and so increase reliability. And they boost high-frequency performance by using copper pillars with much lower resistance than thin bond wires. Flip-chip die bonders have however been slow, so you need a massive investment in multiple machines for any sort of production volume. That is no longer a limitation.

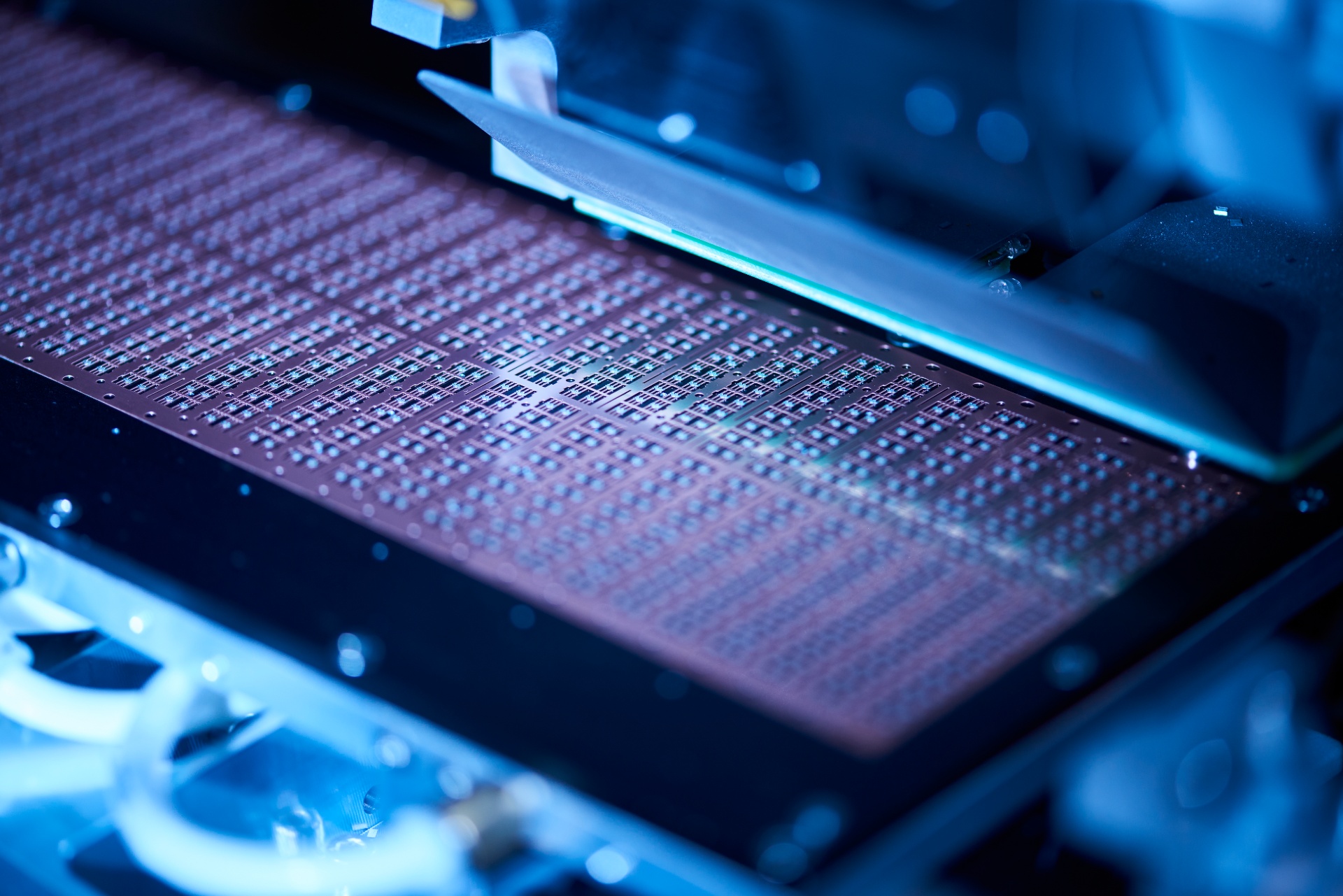

Our new ADAT3 XF TwinRevolve flip-chip die bonder assembles up to 60,000 flip chips per hour, which is at least five times faster than anything else on the market. The new Flagship machine is a game changer, offering a fraction of the Total Cost of Ownership (TCoO) of previous die bonders. You get the same production from a fifth of the factory floor space, and you save on maintenance, operator hours, spare parts and energy costs. It will open a whole new range of applications to flip chips.

The new die bonder simplifies the assembly process. Twin rotating heads mean less inertia and vibration than the conventional forwards-and-backwards motion. The die is flipped and placed in a fast, smooth action with the same accuracy but at much higher speeds. And – as with the whole ADAT3 XF (eXtended Flexibility) family – the machine is automated, modular and field upgradable for extended lifetime and even more sustainable operation.

Performance

Up to 60,000 units per hour

Supports 8 to 12 inches wafer on frame film carrier

Strip size

100 x 300 mm

Die size

Minimal: 0.2 x 0.2 mm

Maximum: 3 x 3 mm

Proven flux screenprint solution available on request

4 cassettes at output (optional at input autoloader)

Full die traceability (strip E142 – wafer)

Auto recipe download (MES interface)

SECS/GEM interface with E142

QFN, DFN, HVQFN, SOT, SO, TSSOP, LGA leadless and leaded packages

Length, width: 0.2 x 0.2 mm to 3 x 3 mm

Aspect Ratio: 1:1 - 1:3

Thickness: 50-400 μm

Minimum length, width: 100 x 40 mm

Maximum length, width: 300 x 100 mm

Thickness: 0.1-1.0 mm

Small die (< 1 mm): XY: 1 σ xy ≤ 4 μm Rotation: 1 σ φ < 1˚

Large die (> 1 mm): XY: 1 σ xy ≤ 4 μm Rotation: 1 σ φ ≤ 0.15˚

Pick and place force: 0.2 - 1.5 ± 0.1 N

Vespel tip

Rubber tip

Push-up needle

Wafer size: 6-12 inches

Wafer frame: 8-12 inches

Steel/Plastic Film Frame Carrier (FFC)

Foil Tension: Programmable expander (8 inches: 1-10 mm; 12 inches: 1-15 mm)

Automatic wafer change and expander

Automatic barcode reader

Twin cross flux dispense module, volumetric dispense

Dot/Cross size, resolution: ≥ 120um 1 σ 20 μm

Dot position: 1 σ < 20 μm

Uph dispense depends on IO-count

Program mode: fast programming for common reject criteria

Reject treatment: strip map (E142) and reject bin

Inspection view: 5 cameras: (1) glue, (2) pre-pick, (3) back, (4) top, (5) post-bond

Length, width, height: 3000 x 2100 x 1250 mm³ (without magazine loader)

Length, width, height: 3500 x 2100 x 1250 mm3 (with magazine loader)

Net weight: 3000 kg (without magazine loader)

Net weight: 3300 kg (with magazine loader)

中文

中文